3D visual inspection

3D visual inspection systems for position recognition, qualitative and quantitative object inspection and 3D object reconstruction.

- 3D image capture (laser triangulation, pattern projection, stereo vision, Time-of-Flight).

- 3D image analysis based on comparison with a 3D model or individual analysis of a complex 3D scene.

- Measurement of 3D dimensions, measurement of dimensions of objects of variable position.

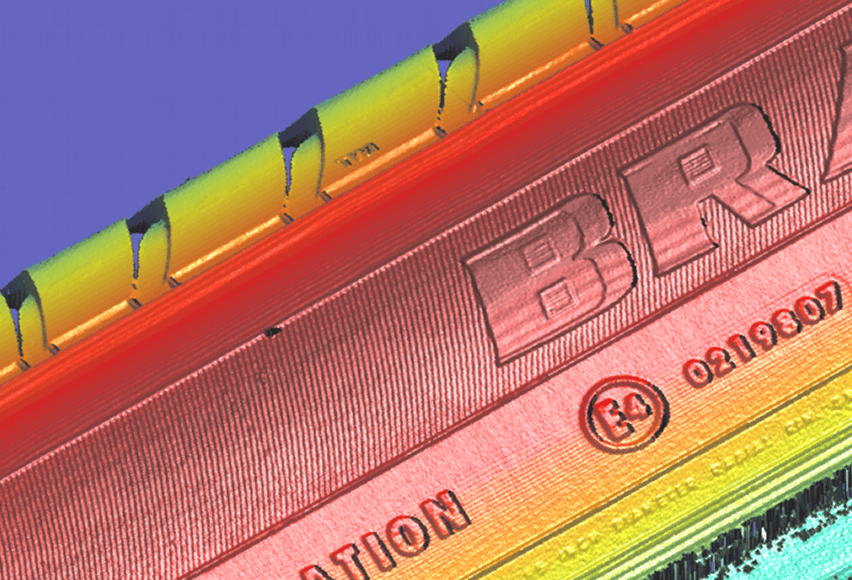

- Inspection of shape and flatness, detection of surface defects (cracks, grooves, etc.).

- Checking the presence and correct position of components (e.g. electrical components, seals).

- Reading 3D text.

Typical application

You don’t know what to do? We will find a tailor-made solution for you.

Use-case

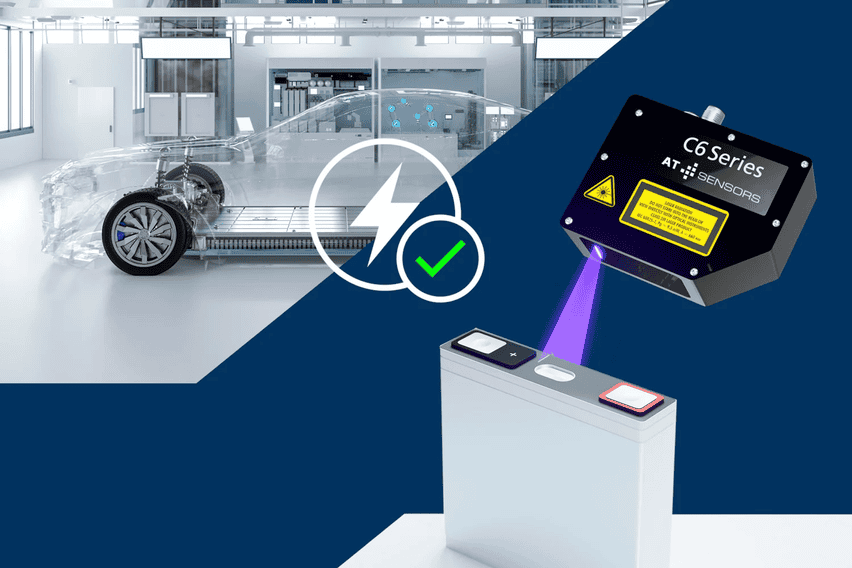

Battery monitoring using 3D sensors

In the automotive industry, precision is essential, and this is of course also true in the manufacture of batteries for electric vehicles (EVs). Malfunctions, short circuits, chemical leaks: these are all serious safety risks to avoid when it comes to electric vehicle batteries, or EV batteries for short.

You can read the full article on how the check is carried out in our e-shop.

Do you need to consult a specialist?

Feel free to contact us directly or use the form below.

System Integration Department

Turnkey solution

Free consultation

Let us help you solve your problem. Contact us and take your projects to the next level!

Other solutions

Machine learning (deep learning) and neural networks

Advanced image analysis using deep learning methods also enables camera inspections in machine vision applications where conventional methods cannot be used.

Checking the application of heat conductive paste and adhesive

Camera systems for quality control of the coating on the base part, on which the electronic part is subsequently deposited. The task is to check the quantity and distribution of the applied paste.

Inspection equipment for the production of automotive headlamps

The system checks the presence and correctness of parts and the completeness of the product during assembly, while allowing electrical and mechanical tests to be carried out.