Inspection in the semiconductor industry

The aim of several projects was to develop and implement advanced systems for optical inspection, prediction and accurate deposition in each key step of semiconductor wafer production – from lithography to final inspection of SMD components.

Emphasis was placed on high precision, adaptation to challenging lighting conditions and the use of neural networks for automated decision making about the quality of the test pieces.

Summary of the benefits of the proposed solutions:

- Increased accuracy and reliability at various stages of production.

- Predictive diagnostics to minimize losses.

- Deployment of neural networks for adaptive inspection.

- Solutions tailored to challenging conditions (optical flare, infrared light, oblique sensing).

Typical application

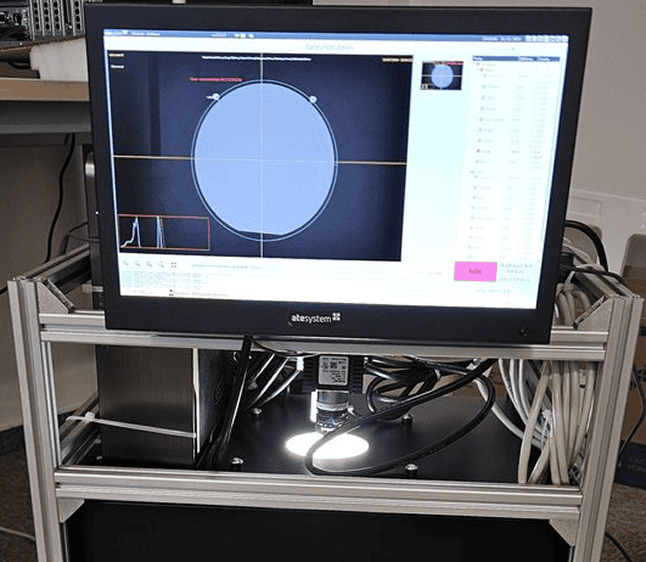

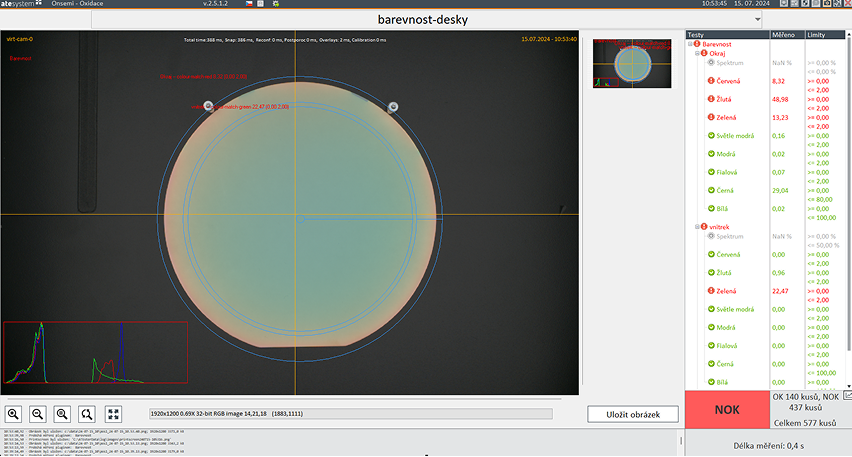

1. Checking oxides on silicon wafers

Proposed solution:

Using a high precision color camera with diffuse illumination to detect color reflections on the wafer surface. The colour shade indicates the thickness and type of oxide.

Result:

The system allows wafers to be sorted based on optical properties (oxide color), increasing yield and reducing the need for manual visual inspection.

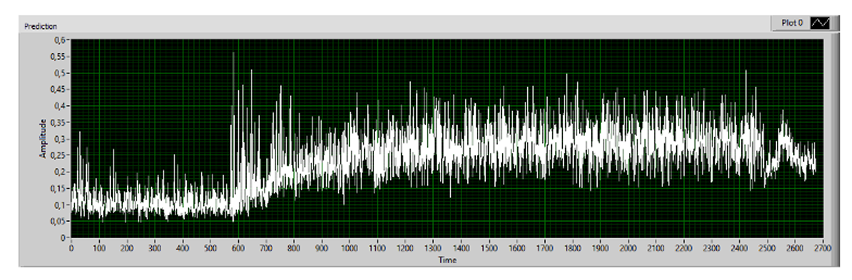

2. Prediction of wafer breakage during lapping

Proposed solution:

Installation of a system with 4 cameras and a neural network monitoring wafer behaviour over time. The deployment of the system is made possible by big data analysis from one year of data collection.

Result:

The prediction algorithm identifies the risk of breakage up to 1 minute earlier than a traditional vibration-based machine system, saving significant costs.

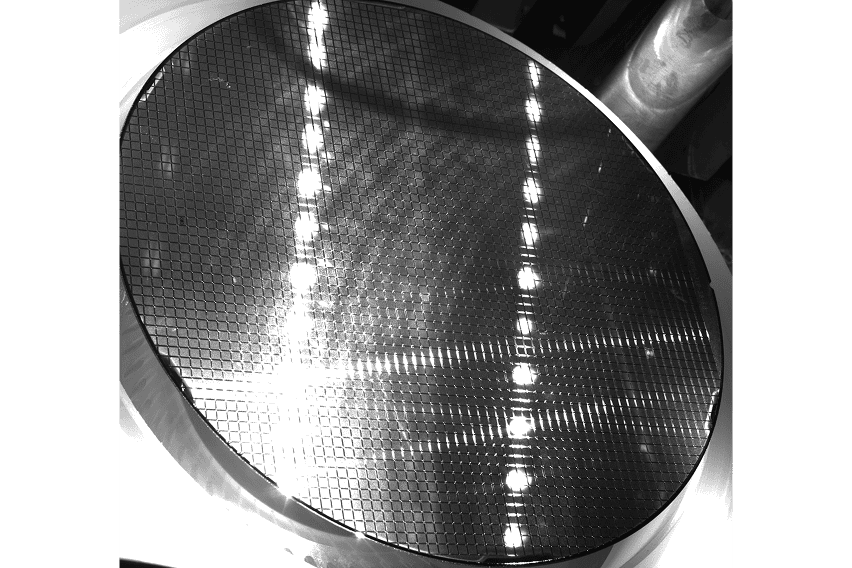

3. Checking wafer seating in lithography

In designing the solution, we addressed the following challenges:

- Deposition tolerance below 0.1 mm.

- Need to eliminate the blue light component → use of infrared lighting.

- Variety of wafer surfaces (glossy, dark, mirror).

- Variety of wafer edge machining.

- Impossibility of direct view → oblique scanning angle.

Proposed solution:

Use of subpixel analysis and mathematical corrections to increase accuracy.

Result:

Ensured high accuracy of wafer position detection even under extreme conditions in the cleanroom.

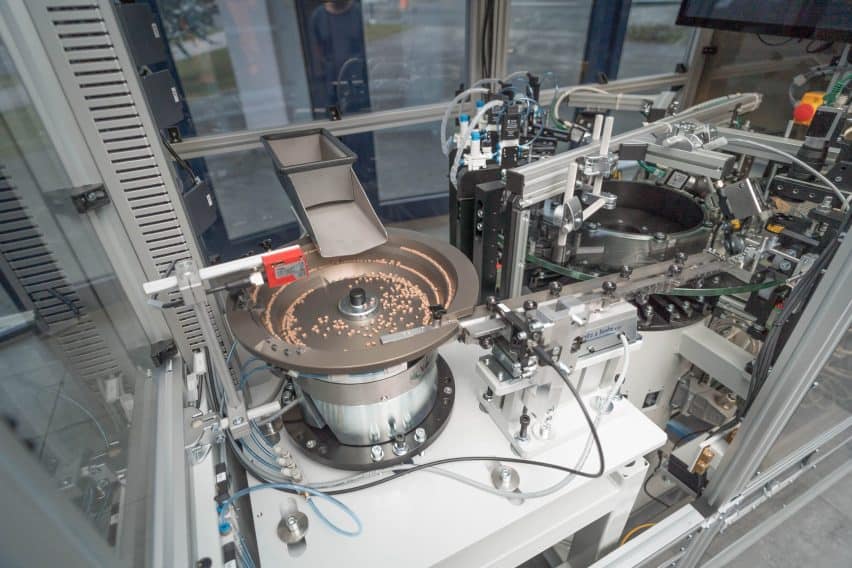

4. Checking the soldering of semiconductor thermistors

Proposed solution:

Complete machine for visual quality control of soldering and final potting. Handling was made difficult due to feeding in a paper blister.

Result:

Provided automated inspection of solder joints without the need for human intervention.

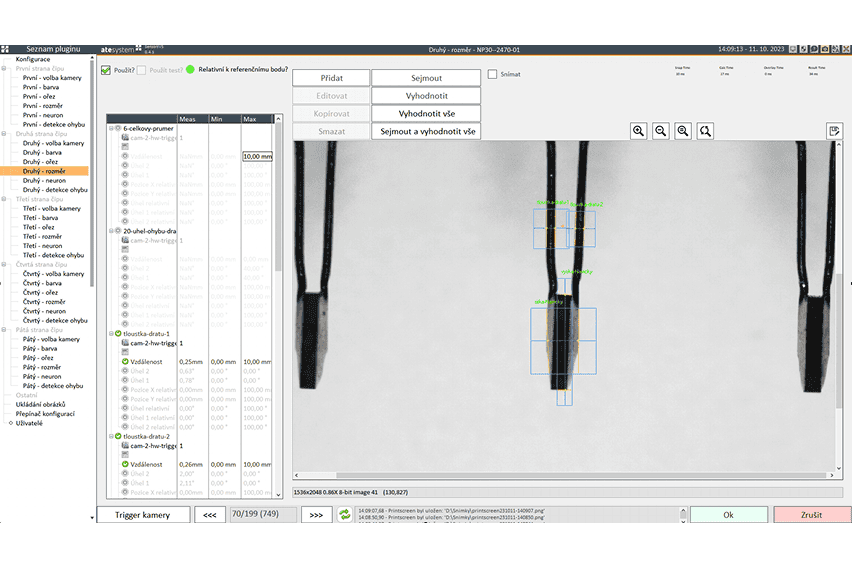

5. SMD component inspection from 6 sides (RTS12G)

Proposed solution:

The RTS12G device allows complete optical inspection from 6 sides at a clock rate of 5 ks/s, with the possibility of using polarized light. The neural network processes up to 300 models per second.

Result:

Complete and fast inspection of shape, colour, marking and possible defects of components.

If you are interested in a project, please get in touch. We will be happy to prepare a tailor-made offer for you.

Do you need to consult a specialist?

Feel free to contact us directly or use the form below.

System Integration Department

Turnkey solution

Free consultation

Let us help you solve your problem. Contact us and take your projects to the next level!

Other solutions

Machine learning (deep learning) and neural networks

Advanced image analysis using deep learning methods also enables camera inspections in machine vision applications where conventional methods cannot be used.

Checking the application of heat conductive paste and adhesive

Camera systems for quality control of the coating on the base part, on which the electronic part is subsequently deposited. The task is to check the quantity and distribution of the applied paste.

Inspection equipment for the production of automotive headlamps

The system checks the presence and correctness of parts and the completeness of the product during assembly, while allowing electrical and mechanical tests to be carried out.