Checking dimensions and shape of parts

Visual inspection systems that detect product defects and imperfections at various stages and processes of production.

- Use e.g. on moulding machines to detect defects caused by imperfect moulding processes

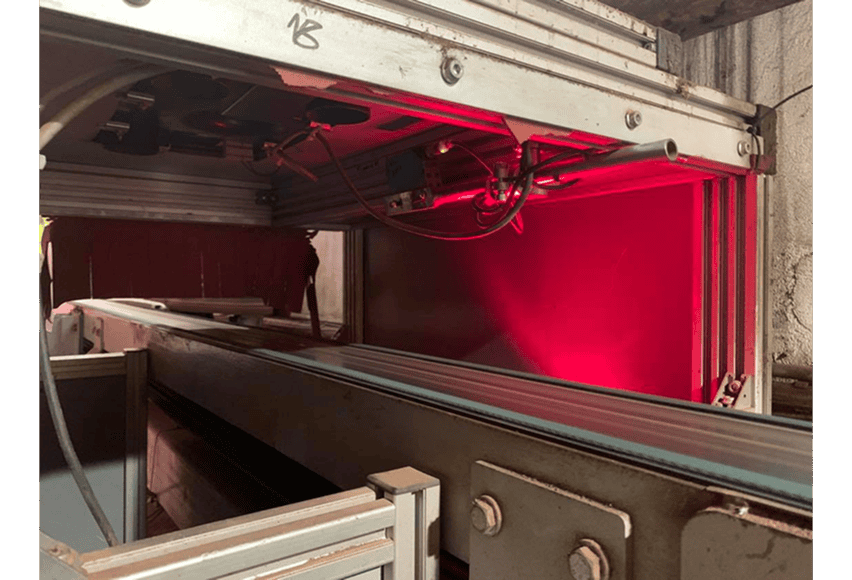

- Camera system with selectable number of cameras, different types of lighting and evaluation unit

- Measurement of dimensions and areas of inspected parts

- Intuitive user configuration of the camera system

- Communication with the control system via TCP, UDP or digital inputs and outputs

Typical application

You don’t know what to do? We will find a tailor-made solution for you.

Success story

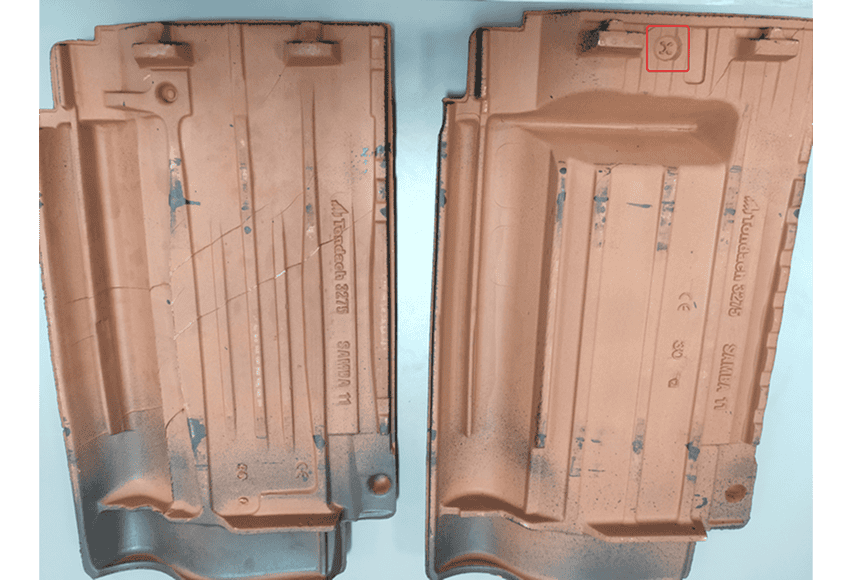

Camera vision based roof tile sorting

The aim is to inspect the products on the conveyor belt, then quickly evaluate the acquired image data and communicate with the PLC system that controls the entire line. Through this process, the different types of roof tiles are sorted.

Continue reading “Success story: what use can machine vision have in construction?” you can find in our e-shop.

Do you need to consult a specialist?

Feel free to contact us directly or use the form below.

System Integration Department

Turnkey solution

Free consultation

Let us help you solve your problem. Contact us and take your projects to the next level!

Other solutions

Inspection in the semiconductor industry

We have developed and implemented advanced systems for optical inspection of wafers, prediction of wafer breakage including control of correct wafer seating in lithography.

Machine learning (deep learning) and neural networks

Advanced image analysis using deep learning methods also enables camera inspections in machine vision applications where conventional methods cannot be used.

Checking the application of heat conductive paste and adhesive

Camera systems for quality control of the coating on the base part, on which the electronic part is subsequently deposited. The task is to check the quantity and distribution of the applied paste.