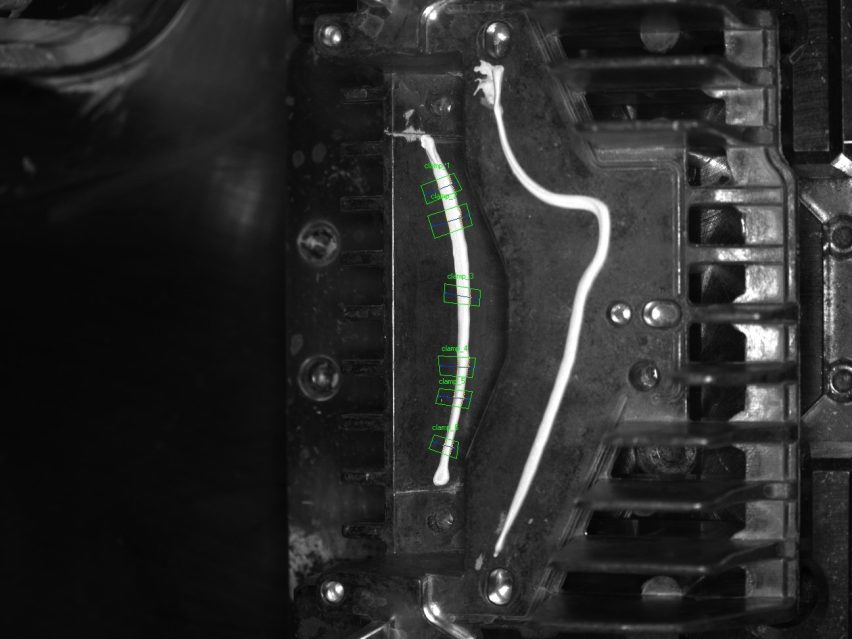

Checking the application of heat conductive paste and adhesive

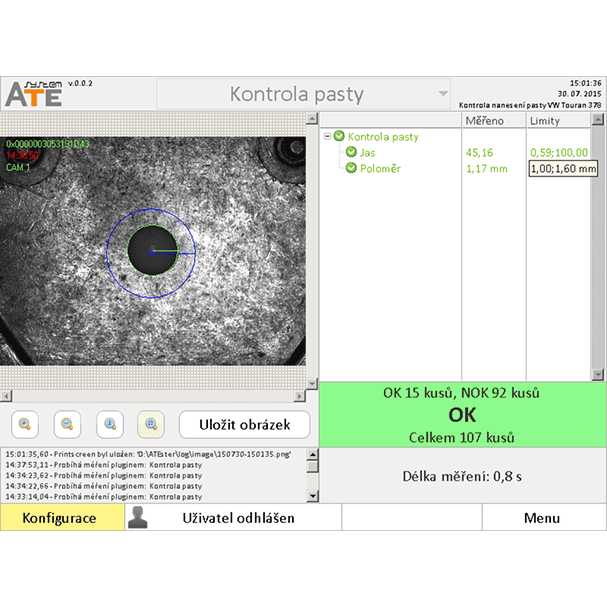

Camera systems for quality control of the coating on the base part, on which the electronic part is subsequently deposited. The task is to check the quantity and distribution of the applied paste.

The quantity is measured at a known viscosity by projection of the trace into the plane, which proves to be sufficiently fast and reliable for production control purposes.

Typical application

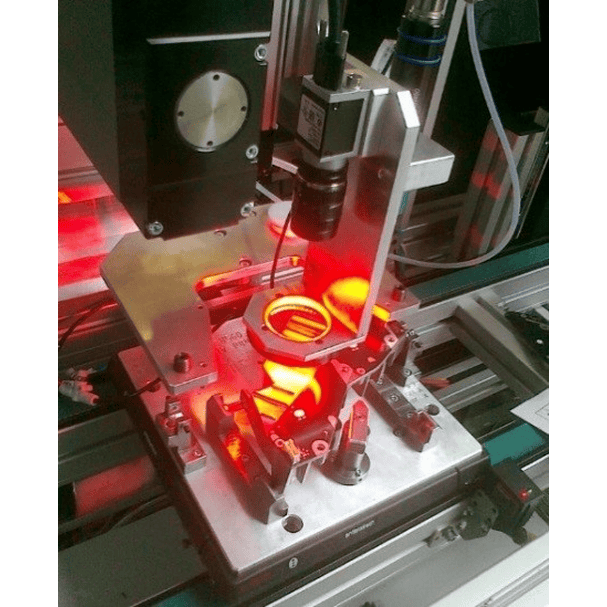

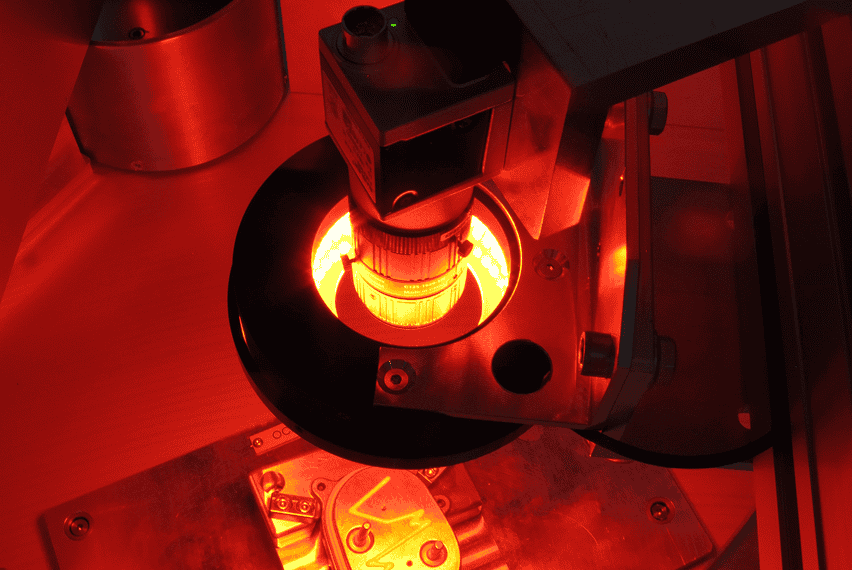

A fundamental part of the camera system is proper lighting, which helps to visually separate the paste or adhesive from the material to which it is applied. The camera, together with the illuminator, is usually mounted on the robot arm in close proximity to the paste applicator so that the positionability of the robot arm can be used to optimally direct the camera and illumination during the test. This type of camera system is usually equipped with a Basler ace camera, which is suitable for robotic applications due to its miniature size. The camera system stores the captured data, including the recording of the images, in a production tracking and data acquisition system.

System parameters

- Measurement of the dimensions, shape and accuracy of the application of the hot conductive paste.

- Dimensional resolution and defects of 0.1 mm.

- Archiving images of unsuitable pieces for later analysis.

- System throughput of more than 1200 pcs per hour.

- Communication with the parent PLC system.

You don’t know what to do? We’ll find a tailor-made solution for you.

Use-case

Implementation of the project of camera inspections and headlight adjustment

Our company successfully completed a project that involved the implementation of camera inspections and adjustment of projectors and headlights on an assembly line for the production of passenger car headlights. The whole project was divided into several parts. One of the first parts was to check the application of the heat conductive paste.

Challenges and solutions:

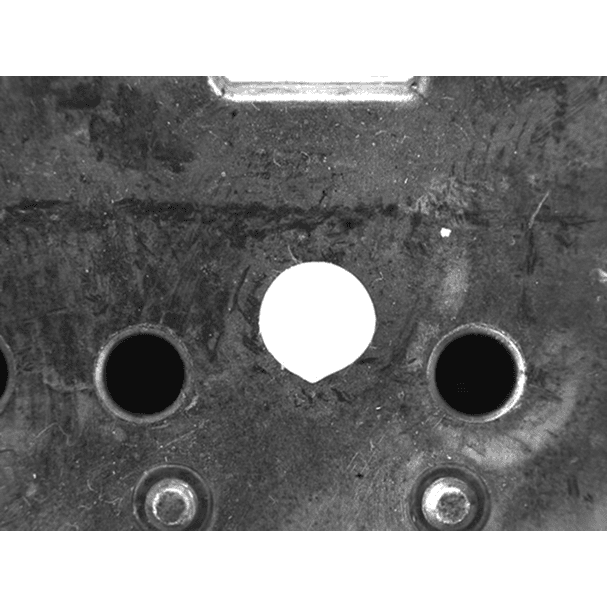

- The main task was to set up the camera, optics and lighting so that the paste was clearly distinguishable from the heat sink, even though the two elements are often similar in colour.

- Key parameters such as area, width and continuity of the applied layer were measured.

You can read about other subtasks in the article“Successful implementation of the camera inspection and headlight adjustment project” on our e-shop.

Do you need to consult a specialist?

Feel free to contact us directly or use the form below.

System Integration Department

Turnkey solution

Free consultation

Let us help you solve your problem. Contact us and take your projects to the next level!

Other solutions

Inspection in the semiconductor industry

We have developed and implemented advanced systems for optical inspection of wafers, prediction of wafer breakage including control of correct wafer seating in lithography.

Machine learning (deep learning) and neural networks

Advanced image analysis using deep learning methods also enables camera inspections in machine vision applications where conventional methods cannot be used.

Inspection equipment for the production of automotive headlamps

The system checks the presence and correctness of parts and the completeness of the product during assembly, while allowing electrical and mechanical tests to be carried out.