Detection and control of product descriptions

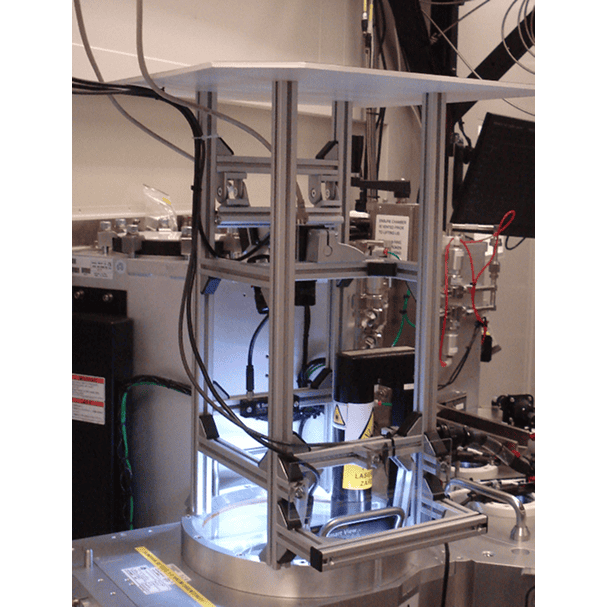

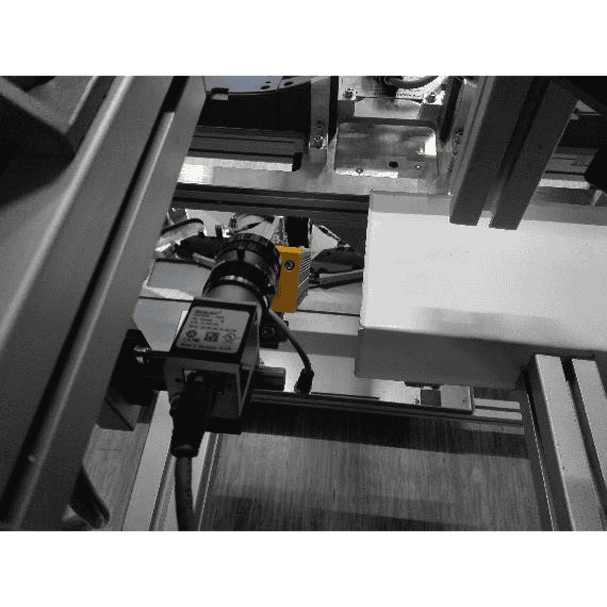

Visual inspection systems monitoring the presence of different types of markings – laser marking, etching, engraved marking, etc.

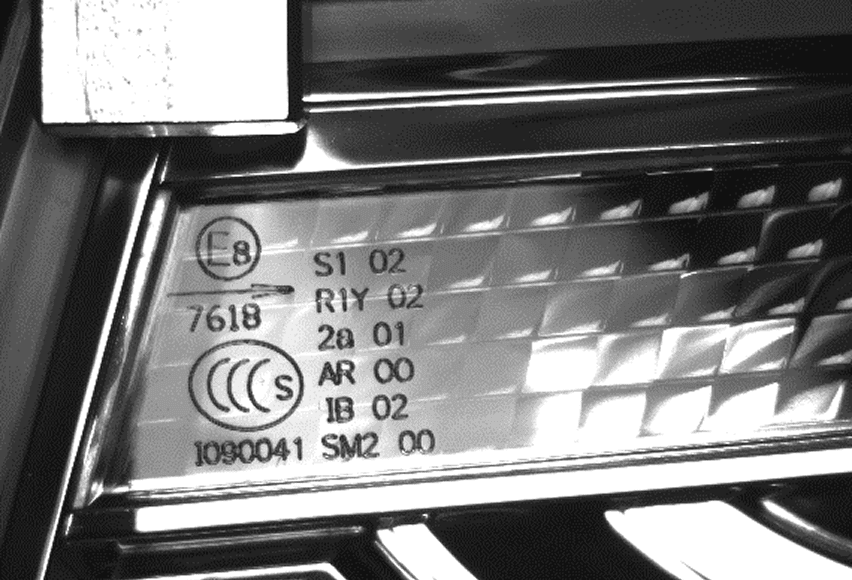

- Checking the correctness of the description

- Recording images in data acquisition and MES systems

- Description detection even under difficult lighting and surface conditions (high-gloss materials, transparent materials, etc.)

Typical application

You don’t know what to do? We will find a tailor-made solution for you.

Succes story

2D code decoding project in Svijany brewery

In this project we cooperated with Svijany brewery. They offer beer that does not undergo pasteurization (heating the beer to a high temperature and stopping the living processes in the beer). Filled kegs are delivered to customers. However, if a keg is stored in a restaurant or shop for longer than the brewery recommends, live beer cultures will multiply. Therefore, when such a keg is returned to the brewery, it requires multiple washings to make it safe for further filling.

Normally, a barrel goes through one wash cycle, but this is not enough to completely wash the barrels returned later. It is therefore necessary to find these barrels, switch off their filling at the end of the washing and filling line and then return them to the beginning of the washing arm.

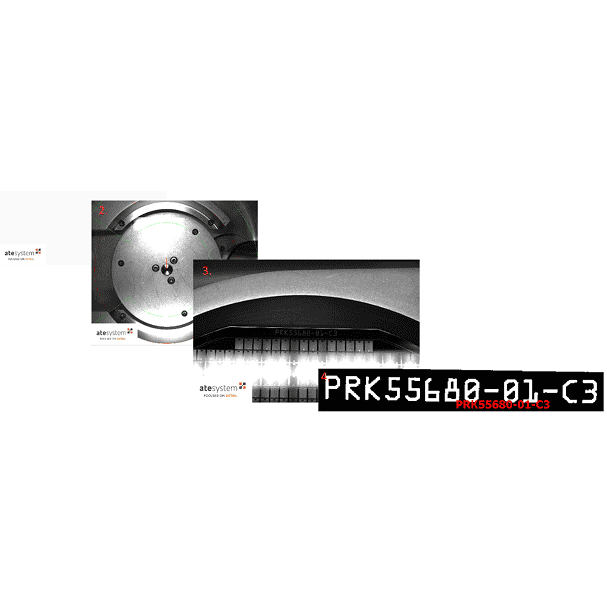

Method of marking the barrels:

The barrels are marked with an aluminium sticker with a data matrix. The 2D code contains the barrel identifier, which is recorded in written form below the code. These stickers are used to mark the barrels sequentially.

You can read the full article on our e-shop –“Success story: the 2D code decoding project in the Svijany brewery“.

Do you need to consult a specialist?

Feel free to contact us directly or use the form below.

System Integration Department

Turnkey solution

Free consultation

Let us help you solve your problem. Contact us and take your projects to the next level!

Other solutions

Inspection in the semiconductor industry

We have developed and implemented advanced systems for optical inspection of wafers, prediction of wafer breakage including control of correct wafer seating in lithography.

Machine learning (deep learning) and neural networks

Advanced image analysis using deep learning methods also enables camera inspections in machine vision applications where conventional methods cannot be used.

Checking the application of heat conductive paste and adhesive

Camera systems for quality control of the coating on the base part, on which the electronic part is subsequently deposited. The task is to check the quantity and distribution of the applied paste.