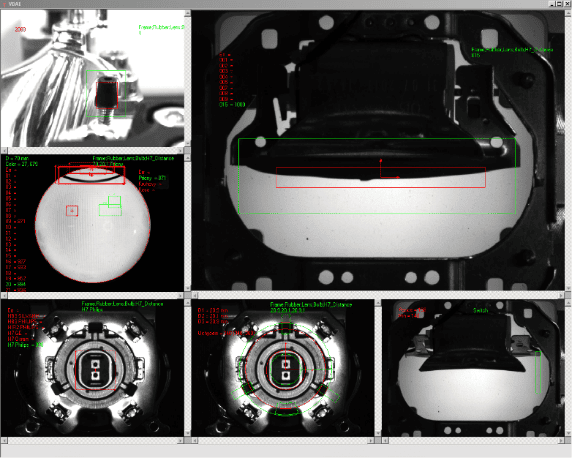

Inspection of assembly and completeness of products

Camera system for checking the presence and correctness of parts during assembly and completion.

- High inspection variability and configurability.

- Detection of the correct position of parts in the jig before and after assembly.

- Automatic or manual activation of the control.

- Interaction with a higher-level system (e.g. PLC) via communication or digital inputs and outputs.

- Use in assembly processes in industrial production.

Typical application

You don’t know what to do? We will find a tailor-made solution for you.

Success story

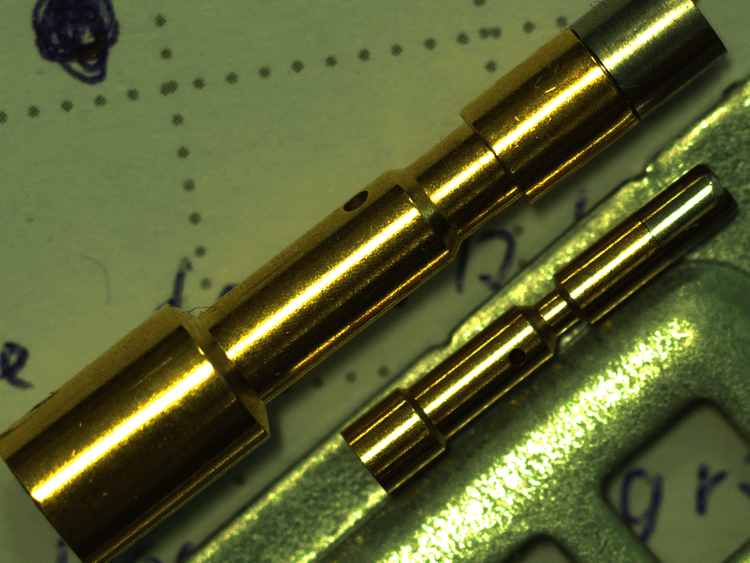

How to check the shape and detect surface defects?

We have integrated a camera system consisting of industrial cameras, illuminators, cabling, control computer including camera system software, developed tailored to the given task. The equipment produced is designed to inspect gold-plated hollow pins in connectors to ensure contact in extreme conditions, such as strong vibrations or large temperature changes.

The principle consists in detecting surface defects, mechanical deformations arising during production, correct assembly and checking for any missing parts.

Read the full article here >> How to check the shape and detect surface defects?

Do you need to consult a specialist?

Feel free to contact us directly or use the form below.

System Integration Department

Turnkey solution

Free consultation

Let us help you solve your problem. Contact us and take your projects to the next level!

Other solutions

Inspection in the semiconductor industry

We have developed and implemented advanced systems for optical inspection of wafers, prediction of wafer breakage including control of correct wafer seating in lithography.

Machine learning (deep learning) and neural networks

Advanced image analysis using deep learning methods also enables camera inspections in machine vision applications where conventional methods cannot be used.

Checking the application of heat conductive paste and adhesive

Camera systems for quality control of the coating on the base part, on which the electronic part is subsequently deposited. The task is to check the quantity and distribution of the applied paste.