Paint layer detection system

Key Features

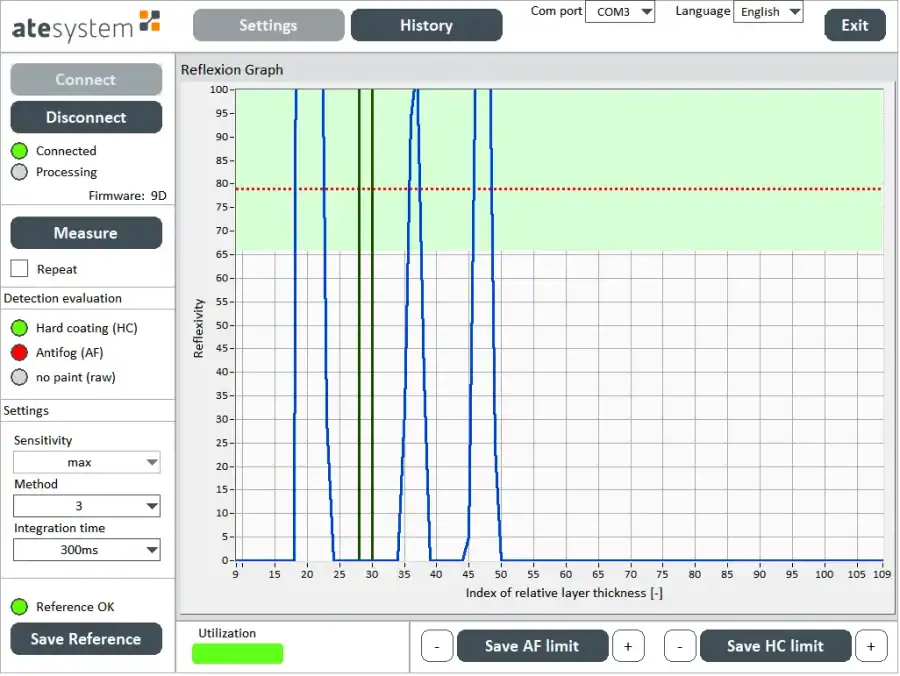

- Local detection of transparent paint layers applied to transparent material according to adjustment in an area of maximum 15 mm²

- Differential method for evaluating the presence of individual layers

- Capable of detecting layer thicknesses ranging from 1.5 to 23 μm

- Evaluating and signalling the presence of a layer according to the limit setting

- System solution for rapid product change/production variations

- Designed for static mounting or mounting on an interchangeable mounting fixture

- Triggering of the detector by a pulse on the signal input

- Storage of the last 54 detections with the possibility of reading them into the PC (permanent memory in the control unit)

- Setup using the PC application “PSKLAK setup” and the cable for the configuration of the detection probe (RS232 interface), or adjustment of the limits using the touch screen (accessory)

- Use of Bluetooth (data transmission) and non-contact (induction principle) power supply for the detection probe

Product description

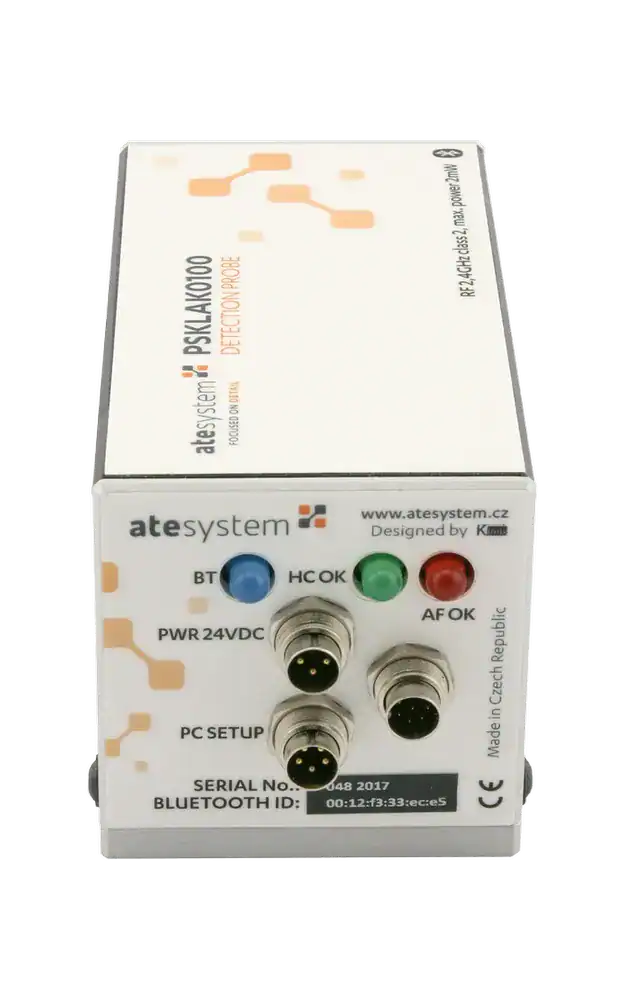

The system is designed to detect the presence of external hard coating (HC) and internal anti-fog (AF) coatings on automotive headlamp covers. Detection is carried out at a point with full transparency of the material over a circular area of approximately 15 mm² (depending on the alignment of the detection probe). The system consists of a detection probe (smart sensor), a control unit and optionally a non-contact power supply system for powering the probe. The detection probe contains its own paint layer sensor and evaluation unit. Signal transmission with evaluation results is possible wirelessly via Bluetooth connection or via cable – direct signals from/to the probe. The way the probe is installed determines the scope of the detection system set.

Sets for installation on interchangeable loading jigs (so-called press heads) allow automatic change of the production product according to the machine design. They contain the same number of detection probes as the fixtures. The control of the active probe is provided by a control unit connected to the machine control system (e.g. PLC). The probe can be powered by a non-contact power supply system (suitable for single-purpose machines such as horizontal presses) or by direct cable (attachment to the robot arm head). Full integration of the paint detection system with mechanical locking of the headlight glass position during detection is used.

Sets for installing detection probes in the static position of the machine workspace (e.g. robot) allow the detection location to be changed variably/dynamically. The robot arm positions the glass to be tested to the desired test point. This method of installation requires the robot to be able to provide repeatable accurate positioning and stability of the arm.

In all of these cases, a detection system is used in a set of detection probes and a control unit from which evaluation states are signalled to the control system.

Another option is to install a separate detection probe using the control and evaluation signals directly from the probe to the control system. In this case, the functionality of the system is limited (no possibility of viewing and archiving the measurements, the cable length must not exceed 5 m).

Sets (number of pieces of individual parts)

PSKLAK | 01xx | 02xx | 03xx | 04xx | 05xx | 06xx | 07xx | 90xx | 91xx | 92xx | 93xx | 94xx | 95xx | 96xx |

PSKLAK1000

Probe for direct control | 1 | 1 | 1 | 1 | ||||||||||

PSKLAK1100

Wired power supply of the probe with the control unit | 1 | 1 | 1 | 1 | 1 | 1 | 1 | |||||||

PSKLAK1200

Contactless power supply of the probe with the control unit | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | ||||

PSKLAK2100

Wired power supply of the probe with the control unit | 2 | 1 | 1 | 2 | 1 | 1 | 1 | |||||||

PSKLAK2200

Contactless power supply of the probe with the control unit | 2 | 1 | 1 | 2 | 1 | 1 | 1 | 1 | 1 | 2 | ||||

PSKLAK3100

Wired power supply of the probe with the control unit | 3 | 1 | 1 | 3 | 1 | 1 | 1 | |||||||

PSKLAK3200

Contactless power supply of the probe with the control unit | 3 | 1 | 1 | 3 | 1 | 1 | 1 | 1 | 1 | 3 |

Components and accessories

| NAME | ORDER NUMBER |

|---|---|

| Detection probe PVD-X002 | PSKLAK01xx; xx - probe revision designation |

| Evaluation unit PVD-Y002 | PSKLAK02xx; xx - revision designation of the unit |

| Unit display | PSKLAK03xx |

| BALLUFF BIC0007 BASE | PSKLAK04xx |

| BALLUFF BIC0008 REMOTE | PSKLAK05xx |

| Bluetooth antenna, 5dBi | PSKLAK06xx |

| Detector power cable | PSKLAK90y0, cable is terminated with BINDER-3p/holes; "y" indicates cable length (3/5/7 m) |

| Bluetooth coaxial cable | PSKLAK91xx, Z=50 Ω, SMA (F/M) terminated |

| Detection probe cable to PC (configuration) | PSKLAK92xx cable is terminated with Cannon-9p/BINDER-5p; length 2 m |

| Cable for connecting the control unit to a display or PC | PSKLAK93xx, cable is terminated with BINDER-4p/BINDER-4p + Canon-9p reducer; length 2 m |

| Power cable to PSKLAK04xx | PSKLAK94xx, cable is terminated with BALLUFF-4p/holes; length 3 m |

| Connection cable for power supply PSKLAK01xx to PSKLAK05xx | PSKLAK95xx, cable is terminated with BINDER-3p/BALUFF-4p; length 0.5 m |

| Signal cable for connecting PSKLAK01xx to the control system | PSKLAK96xx, cable is terminated with BINDER-8p/holes |

Note 1: xx – indicates revision of the product

Note 2: Each packaging contains a USB flash disc with software applications and operating manual for the system for detecting the presence of paint layers. If you need a system which is not included in our product offer, let us know the desiredcomposition of individual product parts, accessories and cabling.

Parameters

| Name | Detection probe | Control unit |

|---|---|---|

| Dimensions (l x w x h) | 103 x 53 x 54 mm | 124 x 64 x 35 mm |

| Weight | 400 g | 300 g |

| Working temperature | 10 to 50 °C | 10 to 50 °C |

| Supply voltage | 24 VDC ± 10% | 24 VDC ± 10% |

| Consumption | 5 W | 4 W |

| Mounting holes | 4 x M4 | |

| Installation | for DIN rail |

Download

| FILE NAME | DESCRIPTION | SIZE | |

|---|---|---|---|

| Catalogue sheet (CZ) | System for detection the presence of paint layers | 1 MB |

|

| Datasheet (EN) | System for detection the presence of paint layers | 3 MB |

|

Do you have any questions about the product?

Feel free to contact us directly or use the form below.

We will find a tailor-made solution for you

We have skills, tools and products to help you overcome challenges. Partner with us to move your projects forward!

Other products

Universal holder with heat sink for sugarcube cameras

The universal camera mount with heat sink consists of four aluminium parts that are screwed together. The sides of the heat sink have milled ribbing to maximize cooling area.

Current source for LED testing

The current source is used to power and test individual LEDs or strings (modules) that do not contain their own electronics that provide current regulation.

ATE-light

Flat lights for direct or back illumination with a durable mechanical construction suitable for industrial environments. Possibility to adapt the light to specific requirements.